ENGLISH

产品说明

|

|

|

|

|

|

Product introduction

Ventilation duct muffler is a principle of resistive sound absorption and noise reduction with good effect on medium and high frequency broadband characteristics. Resistive muffler and sound reduction principle with good effect on low, intermediate frequency and pulsation characteristics, as well as micro-perforated muffler and impedance composite type silencer. Pipe muffler products are mainly used for the effective muffler of steam emissions from boilers, steam turbines and other thermal equipment in the power generation sector.

Usage characteristics

The muffler is a device that prevents sound transmission and allows airflow to pass. It is an important measure to eliminate the dynamic noise of steam emission. To measure the quality of the exhaust muffler, the following three aspects are considered:

1. The noise reduction of pipeline muffler can meet the requirements of "Sanitary Standards for Noise of Industrial Enterprises"

2. Adaptability of pipeline muffler; (that is, adapt to low-medium frequency broadband and high temperature and high pressure, etc.)

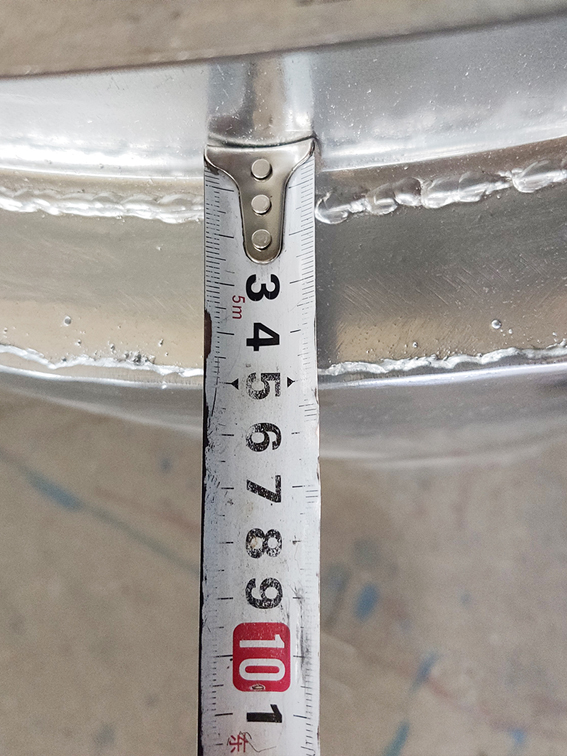

3. Structural performance of pipe muffler. (Reasonable size, low cost, long life, etc.)

The boiler steam in the power generation department not only has high temperature and high pressure, but also has emission frequency bandwidth. It is not possible to muffle only the small holes. Our factory's boiler exhaust muffler is developed based on the principle of compound, muffler, and muffler. , Adapt to the frequency bandwidth, targeted design (low pressure, medium pressure, sub-high pressure, high pressure, ultra-high pressure, subcritical, supercritical and other parameters of various boilers, pressure vessel pipelines exhaust steam venting), the muffler uses stainless steel (1Cr18Ni9Ti, 12Cr1MoV) Advantages of easy manufacturing and installation

Pipe muffler principle

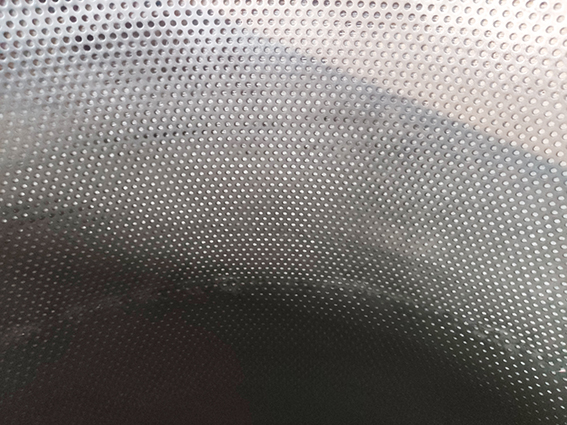

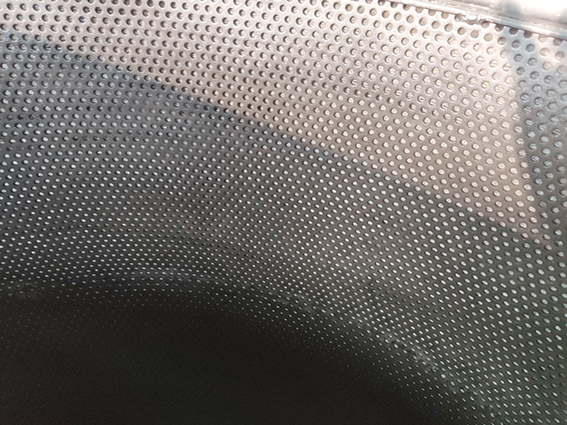

Boiler steam exhaust muffler is based on the principle of micro-perforated plate muffler.The steam discharge from the boiler in the power plant generally has a large flow velocity, and the large flow velocity has the largest impact on the muffler noise, so we need to control the flow first. Then enter the expansion chamber to further reduce the pressure and muffle the sound. After the pressure is reduced by a large volume, the low-pressure steam is ejected. In this process, the airflow is ejected through a small aperture. After the ejection, the sound power of each frequency band has been reduced. , And the frequency of the sound pressure level is pushed up to more than 20000Hz, its noise is greatly weakened, but the secondary noise of some frequencies needs to be further muffled.We have installed a resistive sound-absorbing cotton structure in the expansion outdoor. The spectral characteristics of the residual noise emitted by the step-down body are designed to effectively absorb the residual noise. When the user installs according to requirements, the total muffler volume should reach 30-42 decibels.