Products

Working Principle of Spray Tower

Origin:Hefan Hit: Time:2019-09-07

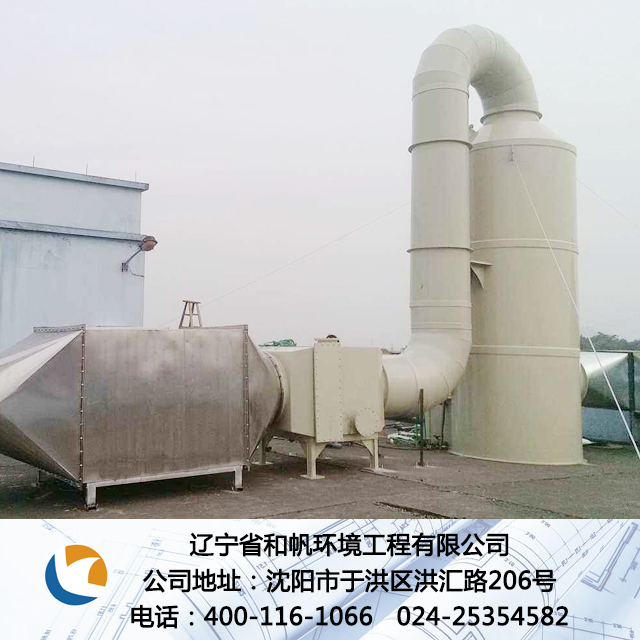

1: Working Principle

The acid mist exhaust gas is introduced into the purification tower through the air duct. After passing through the packing layer, exhaust gas and sodium hydride absorbent are fully contacted with gas and liquid to absorb and neutralize gas. After purification, the acid mist exhaust gas is dehydrated by the dust plate and then discharged into the atmosphere by the fan. After the water pump is pressurized at the bottom of the tower, the absorbent is sprayed on the top of the tower and then circulated to the bottom of the tower. The purified acid mist exhaust gas meets the national emission standards.

2: Characteristics

A. High efficiency of dust removal and desulfurization. When alkali washing water is used, desulfurization efficiency can reach 85%.

B. The equipment occupies less land and is easy to install.

C. Water consumption and electricity consumption index are low.

D. Corrosion resistance, no wear and tear, long service life.

E. The equipment is reliable and easy to maintain.

3: Structure

The spray tower packing layer is used as a mass transfer device for gas-liquid two phase contact elements. The packing supporting plate is arranged at the bottom of the packing tower, and the packing is arranged on the supporting plate in a stacked manner. The packing pressure plate is mounted on top of the packing to prevent upward air flow. The spray tower emits liquid from the top of the tower and reaches the filler through the liquid distributor and flows down the surface of the packing. After the gas is distributed from the bottom of the tower, the liquid is continuously countercurrent through the void in the packing layer. On the surface of the filler, the gas-liquid phase contacts closely to carry out mass transfer. When the liquid flows along the packing layer, sometimes there will be wall flow. The wall flow effect results in the uneven distribution of gas-liquid two-phase in the packing layer, which leads to the decrease of mass transfer efficiency. Therefore, the packing layer in the spray tower is divided into two parts, and a redistribution device is arranged in the middle, and then is sprayed to the lower packing after being redistributed.

4: Applicable Cautions

1: Circulating water flow regulation: determined by spray tower water supply pump, a boiler can be opened when running, two or three pumps should be opened when running simultaneously in winter, and the flow of mud pump should be regulated according to the flow rate that is not allowed to circulate. Let it be equal.

2: the dosage of the spray tower can be increased by adding 2 bags of soda and 5 bags of lime, such as two or three sets, during the operation of the boiler.

3: The tower sedimentation tank should be cleaned regularly, once a week, once in summer and once every three days in winter. When the ash-water separator is discharged, the discharge valve should be opened separately for each shift until clear water is discharged.

4: The above rotating parts should be inspected regularly, oiled and troubleshooted in time to ensure the sulfur removal effect of spray tower rabbits.